Download Project Document/Synopsis

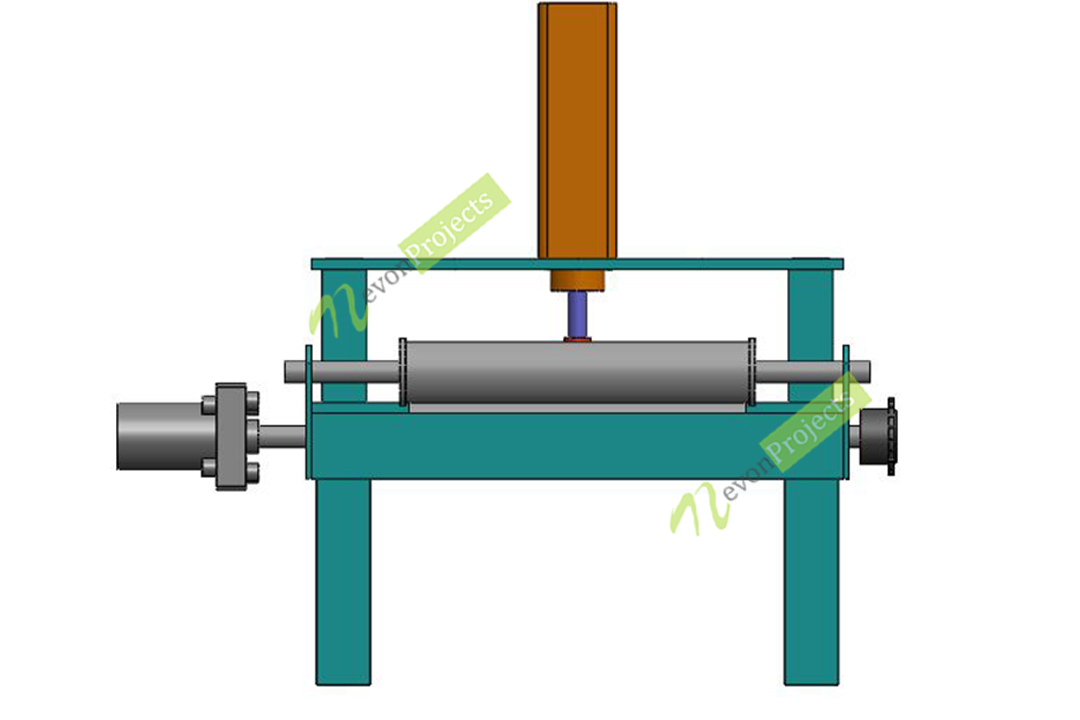

Dimensions: 50 x 45 x 45 Centimeters

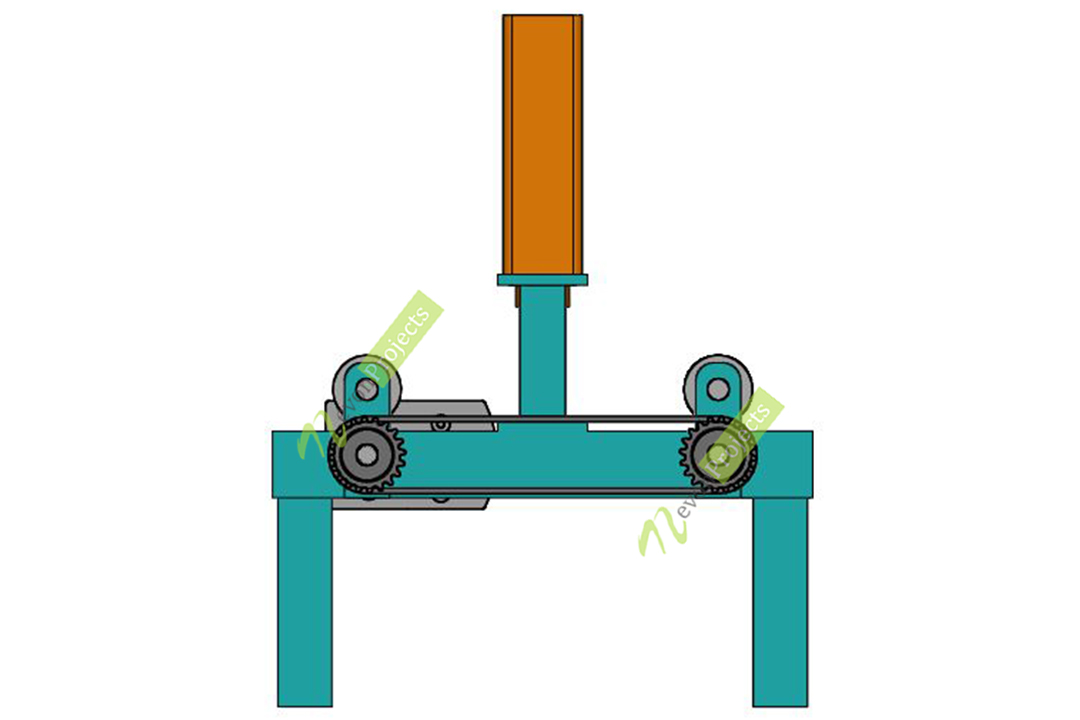

Punching has a wide usage in the industrial world. Holes need to be punched in sheets, pipes of a wide variety of materials for assembly purpose. So here we propose a pneumatic powered punching machine that allows for this with ease. We propose to develop a compact pneumatic punching machine with enough torque to demonstrate hole punching through thin metal sheets. The purpose of this project is to study the punching mechanism and implement it with the help of pneumatic power. For this purpose we first construct a frame to withstand and support the punching system. We then assemble the pneumatic piston and hole support mount into the frame so as to achieve the best punching results. Now we connect the pipes to the cylinder with necessary valves and use a electronic control mechanism to control punching using the pneumatic piston. The system is integrated with motorized rollers needed to feed the metal sheets into the machine. It consists of a metal detection system that automatically detects metal sheets and starts punching process and also pushes the sheet out of other end once done. The electronic system is used to trigger the valves into releasing necessary amount of air into the piston pushing it in needed direction with force needed to punch through the material placed on the bed mount.

- Parts

- Pneumatic Actuator

- Punching head

- Support Bed

- DC Motor

- Roller Shafts

- Chain

- Sprockets

- Pneumatic Pipes

- Pneumatic Fittings

- Pneumatic Valves

- Supporting Frame

- Joints and Mounts

- Metal Detection & Controller Circuit

- Advantages

- Instant and Effective Punching

- Fully Automatic