Download Project Document/Synopsis

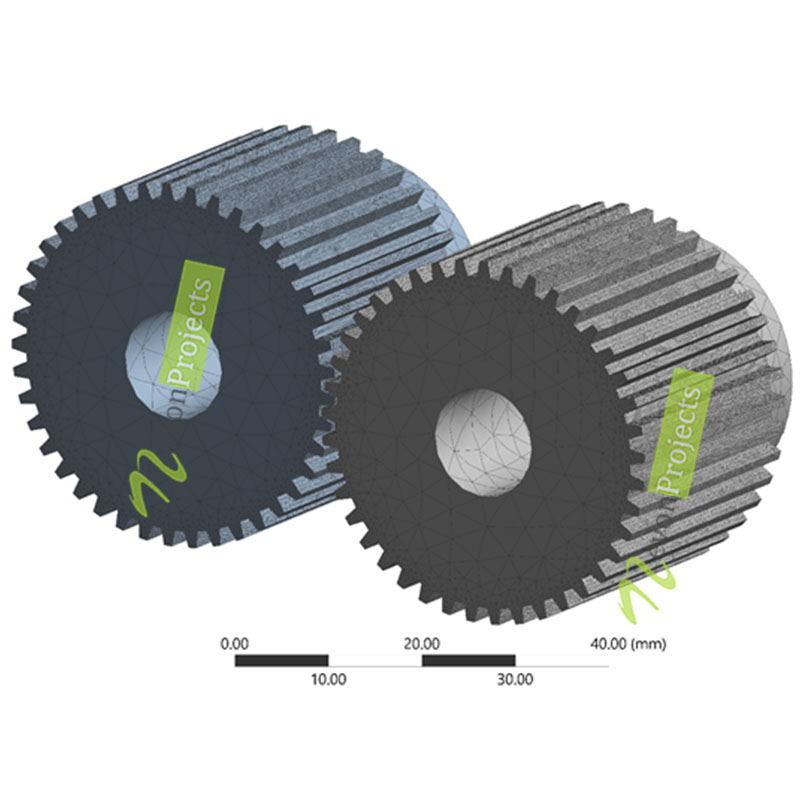

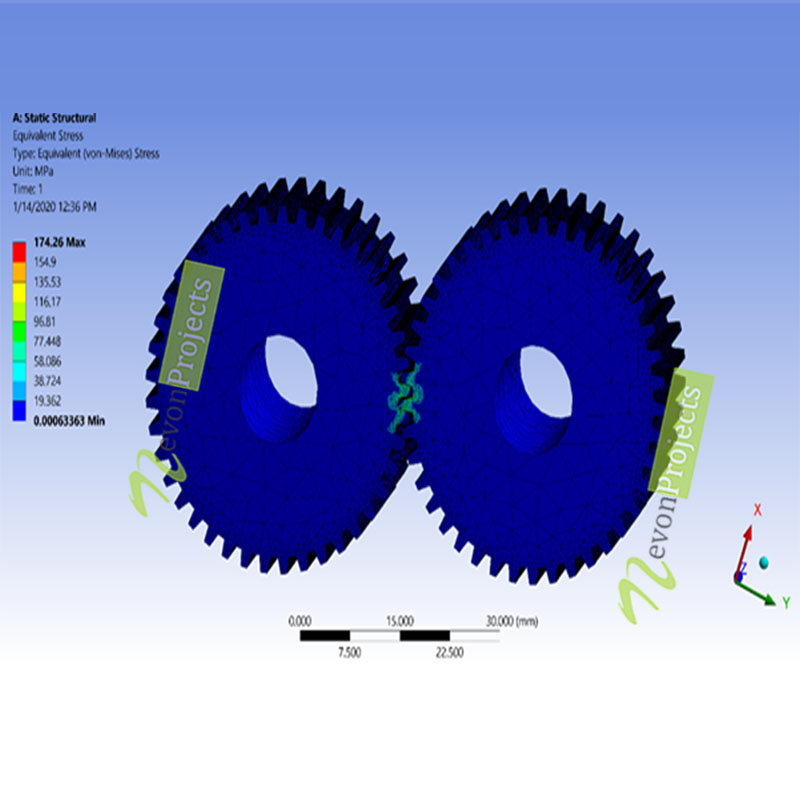

Gears are widely used in all types of machinery in the industry. Ever since gear was known for many years before, they become the integral part of every machine. The initial gear drives were simple and a rod inserted mounted axially. They used to transmit rotational force or circular motion from one part to another. Pair of gears are used with a lower speed cycle. The main difficulty by this system is when the loads and speed were raised the contact stresses were generated at the tip of contact where materials could not withstand these types of stresses due to high wear and contact area. An analysis is done on Footstep power generator project where gear driver is used, analysis is done in Ansys software. 50 Nm torque was used for the simulation to avoid failure. Torque is applied to one of the spur gears and by frictionless support. Other gear was supported by a fixed. A very fine mesh is used for the simulation. It is concluding, Mild Steel gives a factory of safety (FoS) 2.01 for a moment of 50Nm. 2 spur gears are sufficient for the foot-step power generator.