Download Project Document/Synopsis

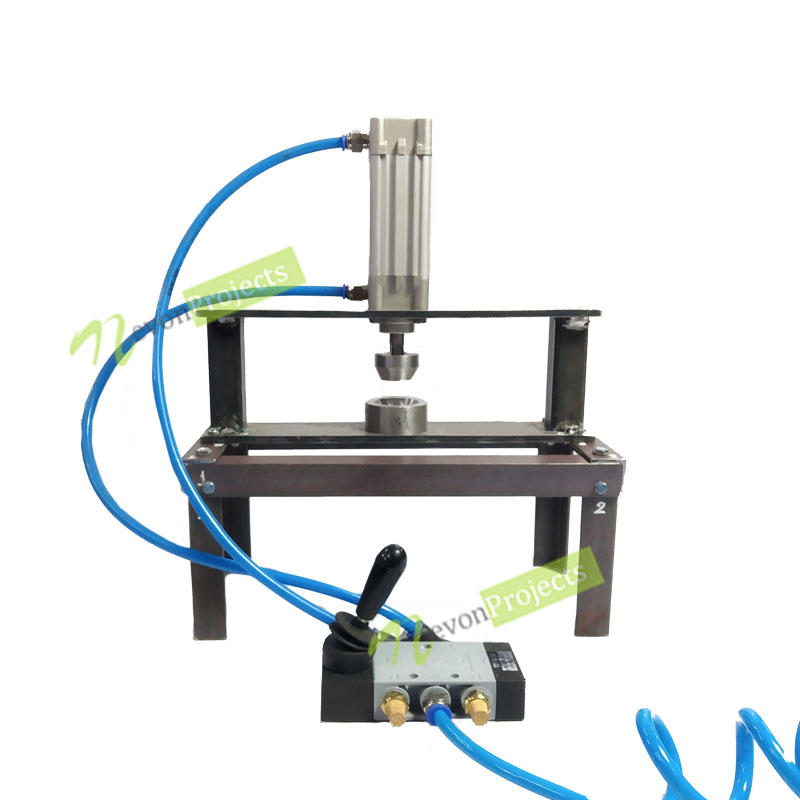

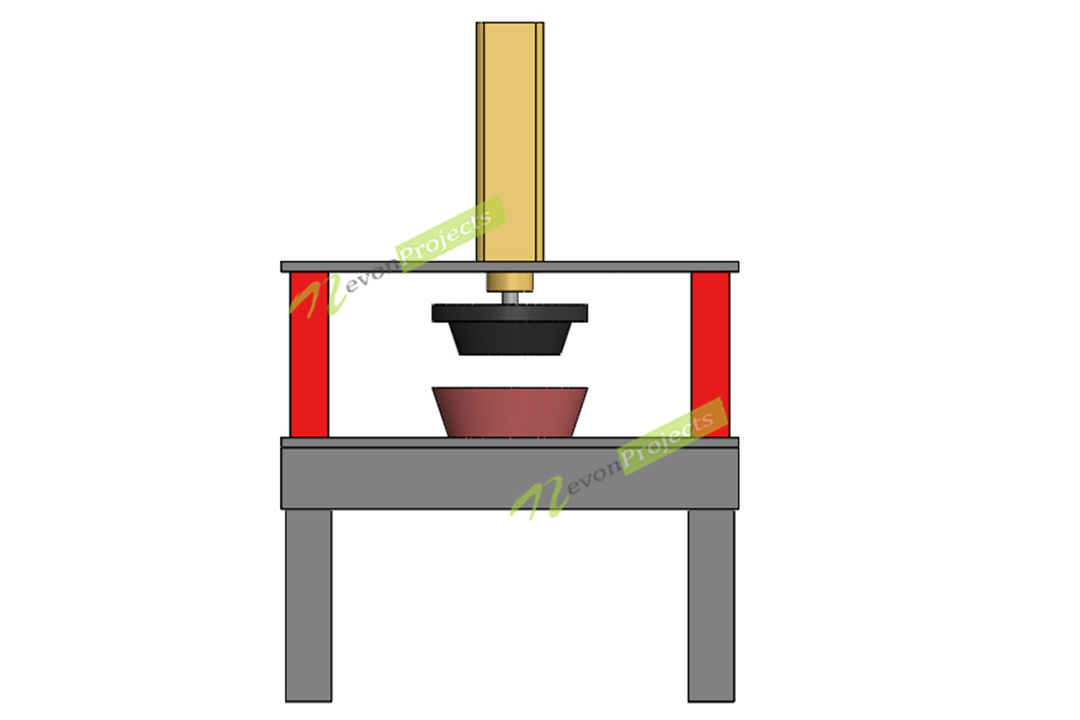

Generally, cups and plates are made in plastics. The plastics are harmful and it has many disadvantages. In a pneumatic system, energy is stored in a potential state in the form of compressed air. Working energy is produced in a pneumatic system when the compressed air is allowed to expand. So, in order to do work, a device is required which is able to supply an air tank with sufficient amount of air at a desired pressure. This device is usually a positive displacement compressor. This fabrication of paper cup making machine consists of the pneumatic punching machine, dye cup, screw rod, top plate, bottom plate, direction control valve, flow control valve, connectors and hoses. Compressor supplies high pressure air to the cylinder, whose flow is controlled by a flow control valve. The air passes through a direction control valve. This is used to actuate the piston and to specify its direction of movement. The piston and punch are the moving parts in this machine. The dye is fixed on the base of the machine by screw rods. The height of the base can be adjusted by rotating the screw rod. The punch, punches the paper placed over the die. The paper placed will be wet. To recover the wetness and make the shape stable a heating coil is placed in the die of this paper cup making machine. The cup can be taken out and the next paper can be placed over the die for the next cycle.

- Components

- Pneumatic Actuator

- Pneumatic Parts & Fittings

- Cup Making Moulds

- Connecting Rods

- Base Frame

- Mounts & Joints

- Screws & Fittings

Block Diagram