Download Project Document/Synopsis

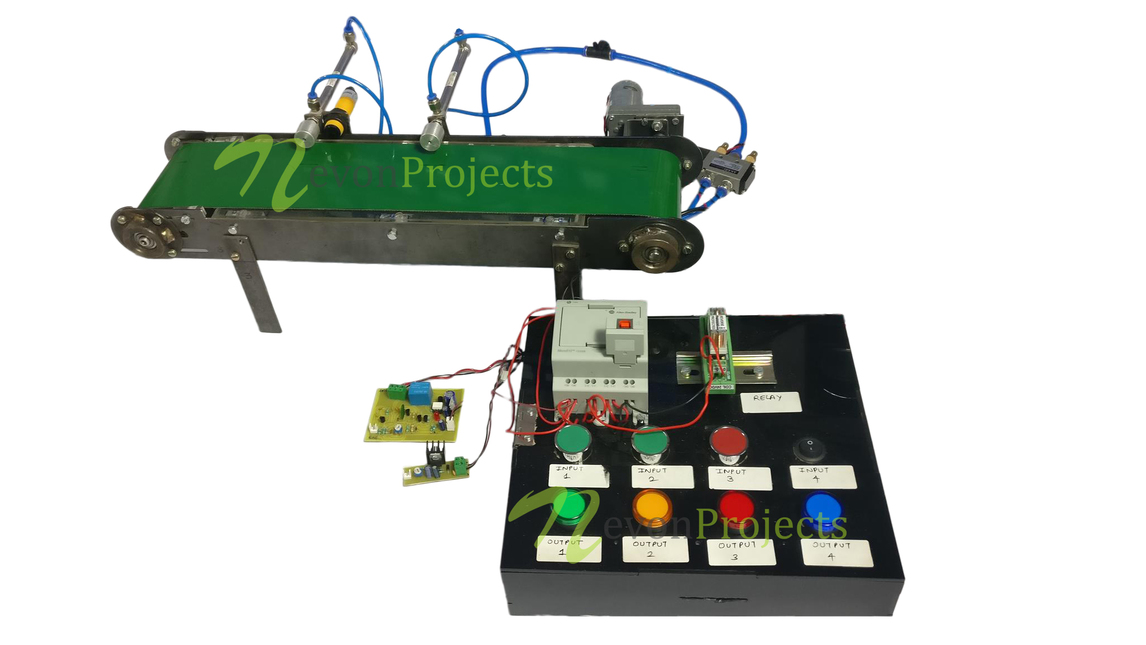

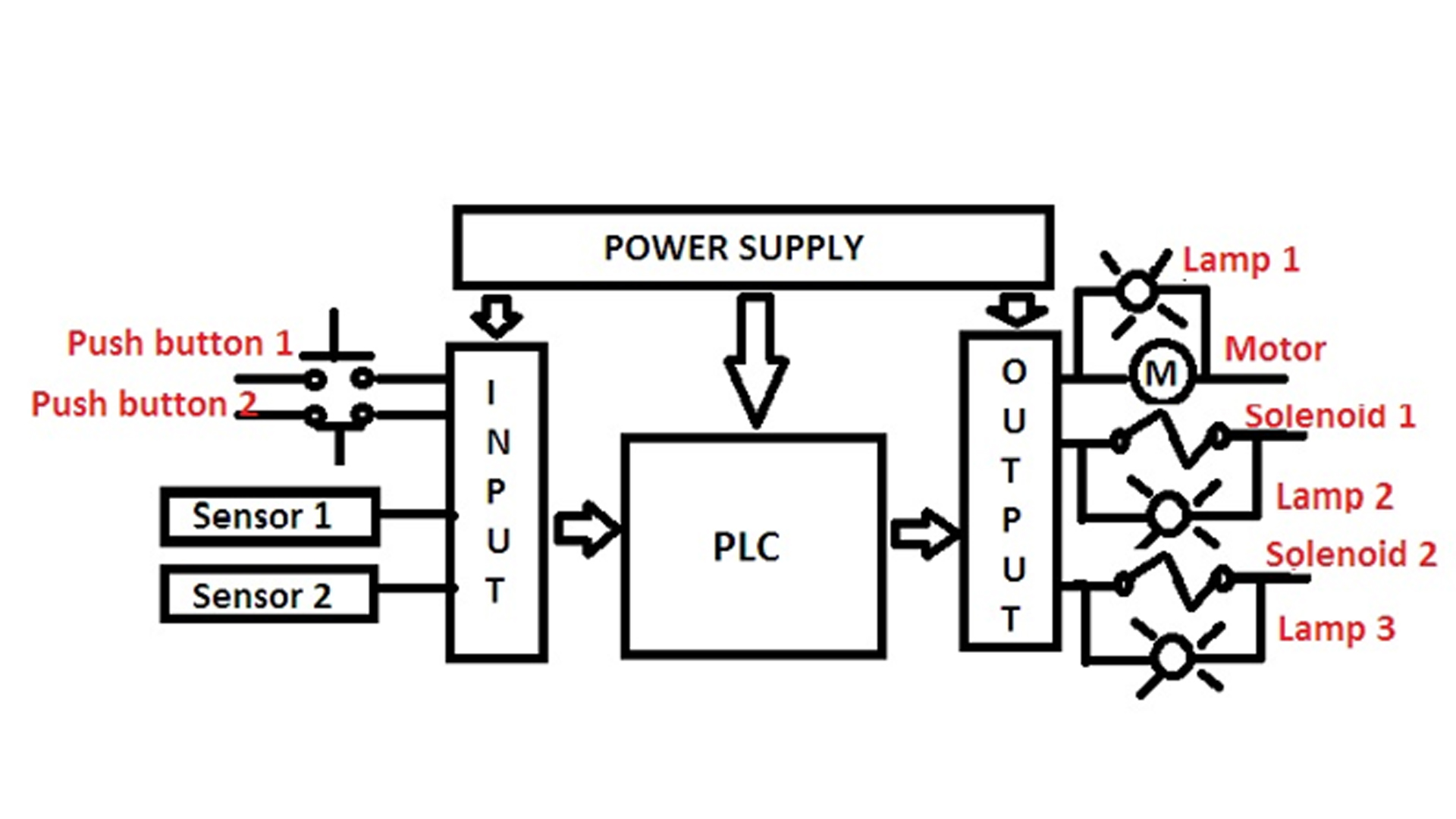

Here we propose the concept of “PLC Based Sorting System Using Metal Detection”. As the name suggest this sorting machine project consist a PLC (programmable logic controller) to automate the machine. This system of sorting products is optimized to differentiate between product on the basis of their metallic property, which is done with the help of a metal detector. A continuous conveyor belt carries the products and a pair of pneumatically actuated pistons pushes them in the sorting bin.

In a nutshell, this system two sensors, a metal detector and a proximity sensor. When the conveyor belts carries the products, it goes through a metal detector, if it’s a metal product the first piston push the product to the container, and the skipped product goes further to the second piston, which detect the incoming product using the proximity sensor and push the product into another container. These pistons are pneumatically powered. All this functions are precisely controlled by a PLC.

- Parts

- Programmable Logic Controller (PLC)

- Pneumatic Actuator

- Pneumatic Pipes

- Valves

- Motor

- Shaft

- Conveyor Belt

- Proximity Sensor

- Metal Detection Sensor

- Connecting Rod

- Roller

- Mounts

- Supporting Frame

- Joints & Fixtures

- Screws

- Advantages

- Accurate Sorting Results

- Efficient & Portable System