Download Project Document/Synopsis

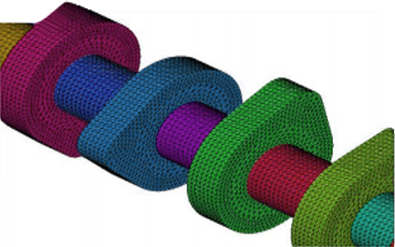

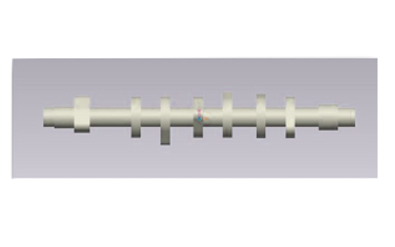

The behavior of camshaft is obtained by analyzing the collective behavior of the elements to make the camshaft robust at all possible load cases. This analysis is an important step for fixing the optimum size of a camshaft and knowing the dynamic behaviors of the camshaft. Initially, the model is made by the fundamental desires of an engine with the out their background information like the power to be transmitted, forces acting over the camshaft by means that of valve train whereas running at most speed. Here the approach becomes fully CAE based. CAE based approach enriches the Research and limits the time duration. Camshafts are rotating components with critical loads. Hence the determination of actual load values becomes the difficult one compared with alternative rotating members.

This Research provides guidelines to solve such a situation. The objective is to determine the strain distribution on the camshaft for each static and dynamic case and sorting out the issue of safety. We found that the factor of safety is that the ratio of yield durability to the look strength for ductile materials and supreme durability to the look strength. From the FEA output, the maximum design strength is 240.6 N/mm2 from the material property the ultimate tensile strength of the material is 720 N/mm2, then the factor of safety becomes within that safety limit.

Reference Paper Link: https://www.ijert.org/research/finite-element-analysis-of-nodular-cast-iron-camshaft-IJERTV6IS050132.pdf