Download Project Document/Synopsis

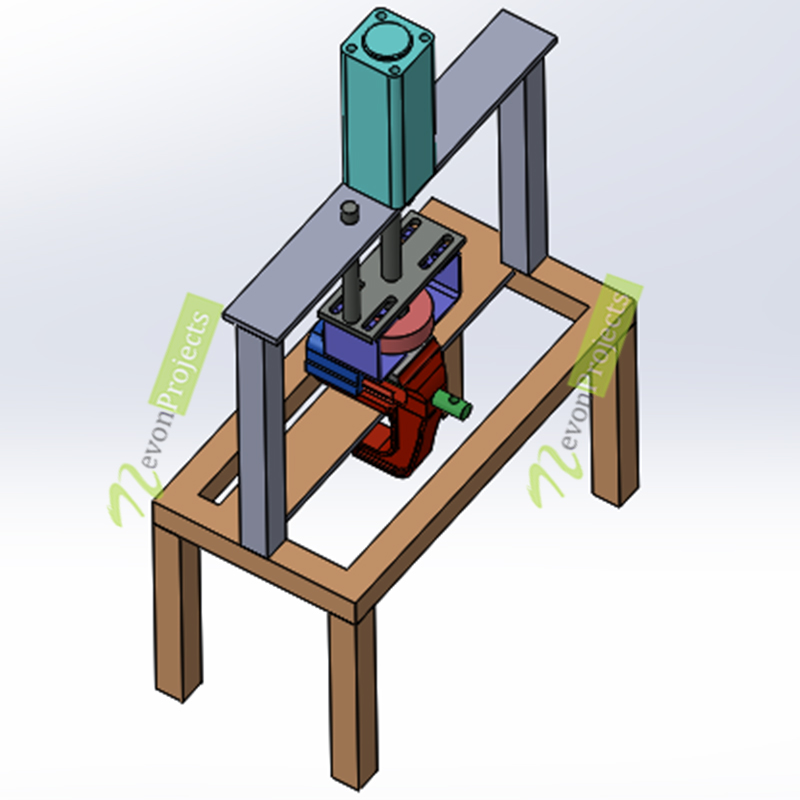

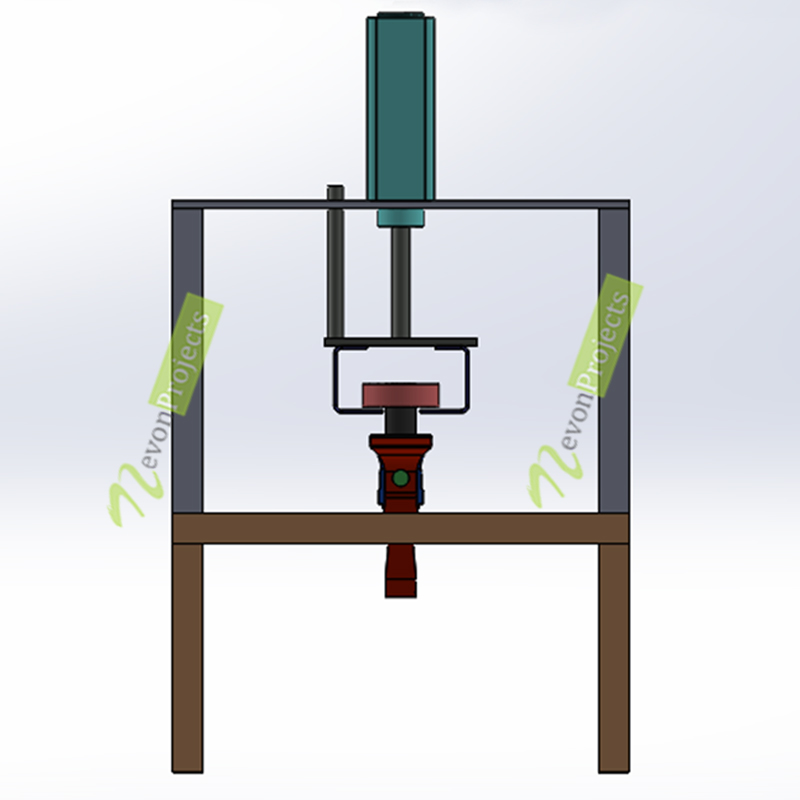

A bearing is a part of a machine such as an engine that compels relative motion. This helps to reduce friction between the moving parts. A bearing puller is a tool used to remove bearing sets from a rotating machine shaft or from a blind bearing hole. The most common application is removing a caged set of ball or tapered bearings from a rotating shaft. Traditional method of bearing removal is hammering which causes several problems. In the machine the press fit operations are very complicated to align the assembly, this type of operations requires heavy force for dissembling the bearing from the machines. The Pneumatic bearing puller performs pulling operation safely and without harming bearing surfaces. This pneumatic bearing puller system can be widely and effectively used for removing the bearing. Nowadays pneumatic system plays an important role in almost all applications. This bearing puller consists of pneumatic cylinder, actuator, puller and vice. Pneumatic cylinder uses air pressure to unmount the bearings.

- Components

- Metal frame

- Pneumatic cylinder

- pu pipe

- Pneumatic connectors

- Solenoid valve

- Vise

- Links