Download Project Document/Synopsis

Suspension systems must support both road holding/handling and ride quality, which are at odds with each other. The tuning of suspensions involves finding the right compromise. It is important for the suspension to keep the road wheel in contact with the road surface as much as possible, because all the road or ground forces acting on the vehicle do so through the contact patches of the tires. The suspension also protects the vehicle itself and any cargo or luggage from damage and wear.

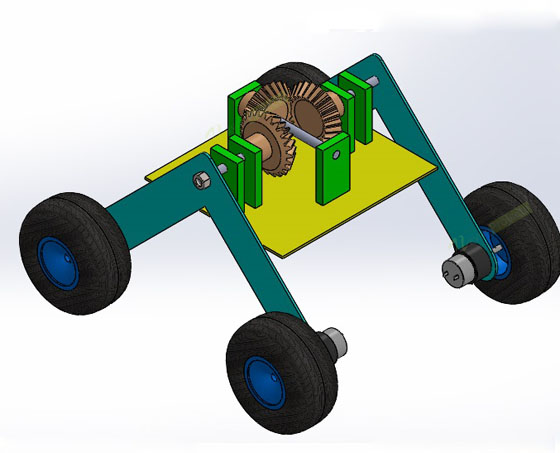

Our Project, The Springless Suspension System Combines a differential mechanism and an oscillating system. A differential is a gear train with three drive shafts that has a property such that the rotational speed of one shaft is the average speeds of the others, or a fixed multiple of that average and Oscillation is the repetitive or periodic variation of an object.

The Frame of the system is mostly made of Mild steel. The frame that holds the tires oscillates freely. The same frame is connected to the differential.

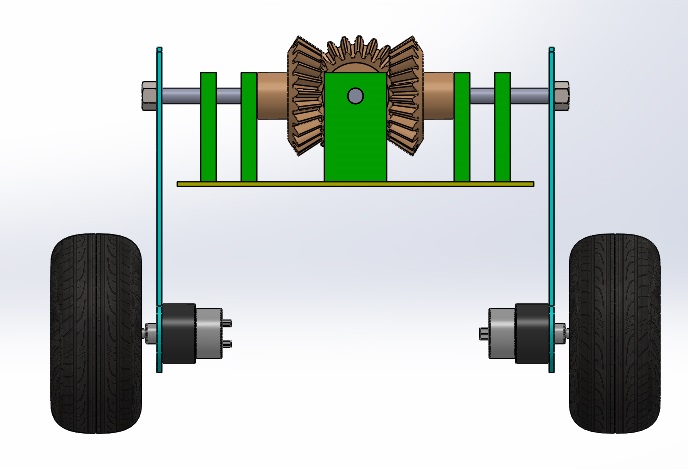

A motor is connected to a gear in the differential mechanism, thereby making it the driving gear. The driving gear is connected by bevel gear on both the side. Each gear is connected to two wheels on each side. Each wheel is driven by an individual motor. The motor makes sure that the gears and the wheels are in motion and the oscillating property makes sure that the vehicle is moving forward even in rough terrain.

- Compenents

- DC Motors

- Bevel Gear

- Wheels & Tires

- Motors

- Supporting Frame

- Nuts and Bolts

- Connecting Rods

- Bearings

- Supporting Frame

- Nuts & Bolts

- Mounts and Joints

- Base Frame

- Screws and Connectors

Front View

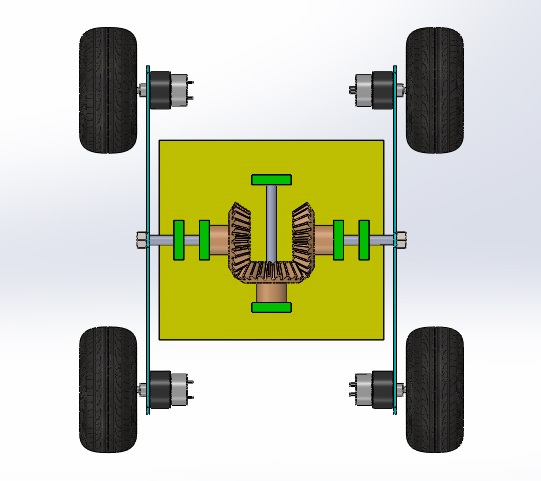

Top Views