Download Project Document/Synopsis

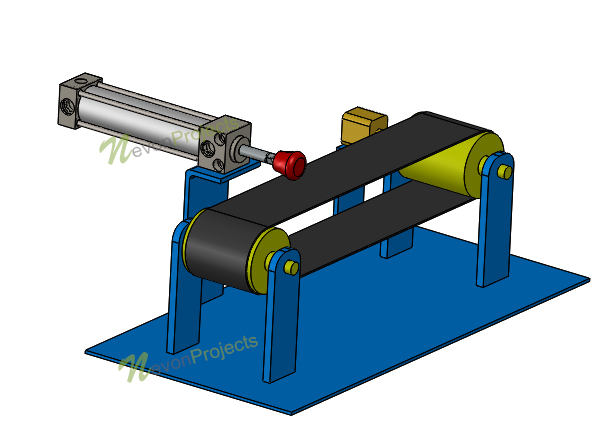

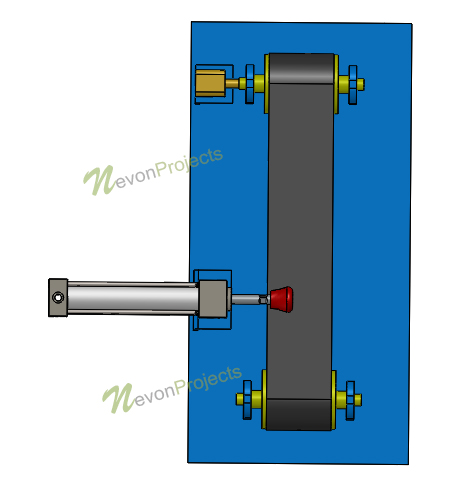

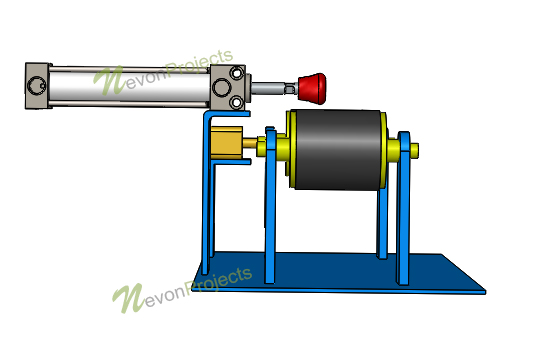

Here we demonstrate the use of an automatic, pneumatic based material separation system that allows for separation of materials placed on a conveyor belt using pneumatic separator. The system makes use of a conveyor belt made of 2 rollers powered by a motor and a rubber belt over it. We make a metal frame to support the conveyor motion. The system consists of a sensor that allows to detect if the product is to be kept of to be discarded based on its height. We use a control circuitry in order to detect objects and to decide weather to keep it or push it aside. The system constantly checks for sensor values and if the sensor value indicates a faulty product, the system activates the valves and this drives air through the cylinder thus driving its piston. This pushes the faulty product out of the conveyor belt. The products without defects are allowed to pass through the conveyor without stopping. Thus we demonstrate the operation of a fully automated pneumatic based material separation system.

- Parts

- Conveyor Belt

- Pneumatic Actuator

- Push Bed

- Proximity Sensor

- Pneumatic Pipes

- Pneumatic Fittings

- Pneumatic Valves

- Supporting Frame

- Mounts & Joints

- Electronic Circuit

- Advantages

- Smart Detection Of Materials

- Automatic Separation

- Low Power Consumption