Download Project Document/Synopsis

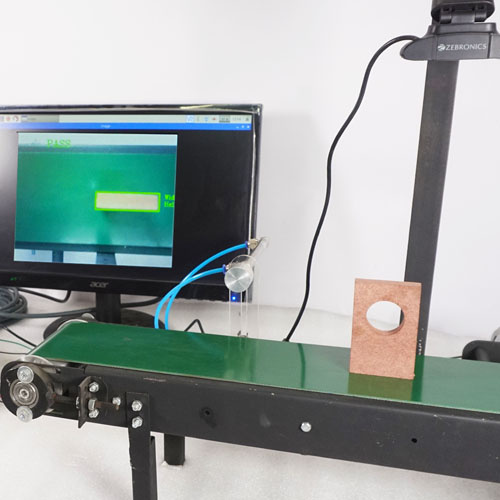

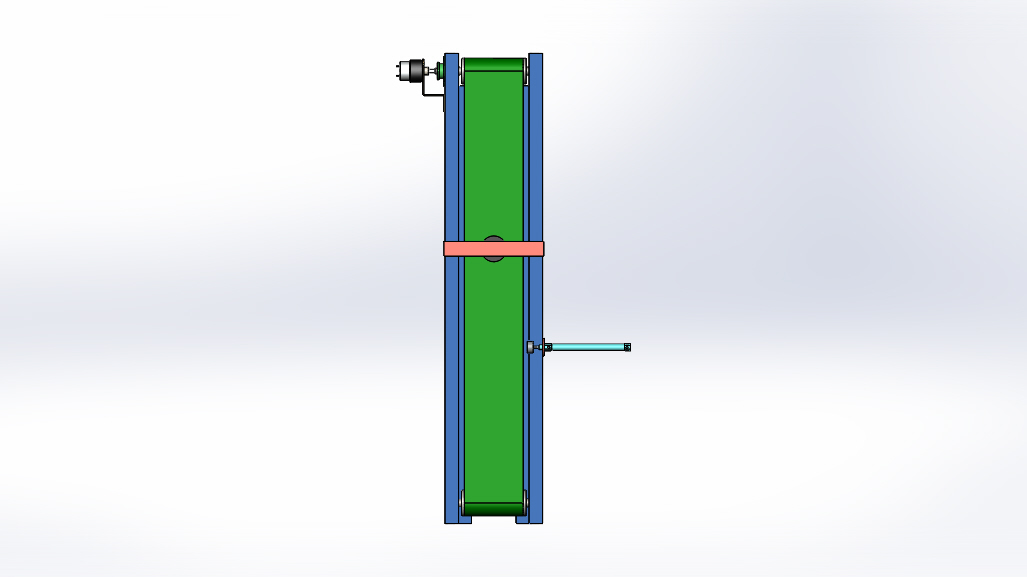

Image processing or computer vision is a technical discipline that deals with searching the ways to automate all the work that a human visual system can do. There is a clear growth and development in the field of automation both in industrial and residential areas. The product sorting process plays an important role as these industries cannot afford any human errors for sorting products. The use of image processing to automatically sort objects based on their shapes, size or colour is the best method to avoid any type of error. In this PLC based system, different size objects are placed on the conveyor. At the top, the camera is mounted which is connected to Raspberry Pi. The camera and Raspberry Pi analyse the object and the dimensions of the objects are detected. Then the signal is sent to the PLC if the object is to be accepted or rejected according to dimensions of the object. Then the Solenoid is actuated and the pneumatic cylinder pushes the rejected object from the conveyor.

- Components

- Aluminium conveyor

- 12V DC Square Box Motor

- 5/2 Solenoid Valve

- Double Acting Pneumatic Cylinder

- Raspberry Pi

- Delta PLC

- Relay Card

- Buttons

- Webcam

- Camera Mounting