Download Project Document/Synopsis

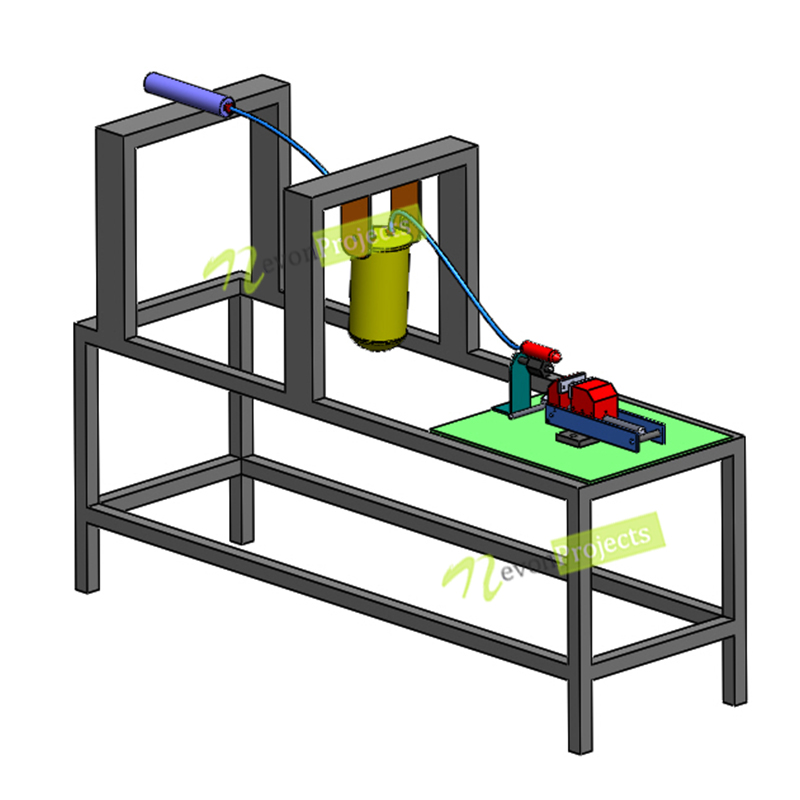

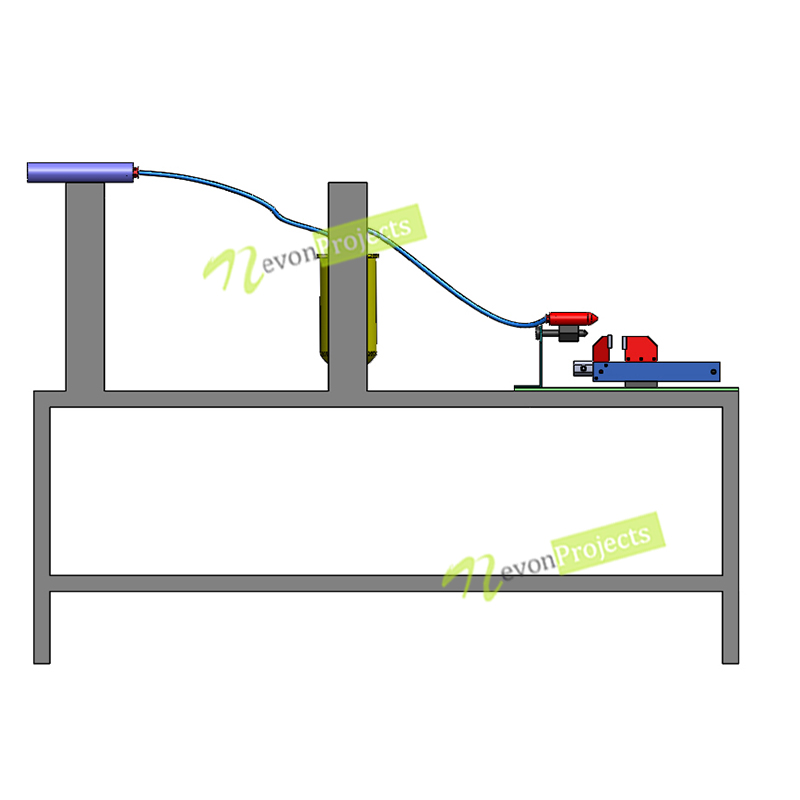

This abrasive jet machining project is used for cutting any integrated shapes on brittle materials like glass. We can cut any difficult shapes and create holes in glass and brittle material using compressed air and abrasive particles. Here sand is used as abrasive material. A compressor is used which is connected through PU pipe to control valve. Control valve controls the air through pipes to the nozzle. There is pressure gauge which is attached to measure the pressure through a pipe. Pressure relief valve is also a filter which is attached between a control valve and nozzle which cleans the air and passes to the mixing chamber. The function of the mixing chamber is to mix clean air with the sand or abrasive particle with high pressure. The abrasive particle can be poured from the upper inlet of mixture chamber. Discharge of this mixing chamber is connected to a nozzle. Nozzle increases the velocity of high pressurized discharged air mixed with abrasive particle. This discharged air impacted on the glass or any brittle material held by the vice. Thus, the required holes can be achieved.

- Components

- Compressor

- Mixture chamber

- Nozzle

- PU fittings

- Bench vice

- MS frame