Download Project Document/Synopsis

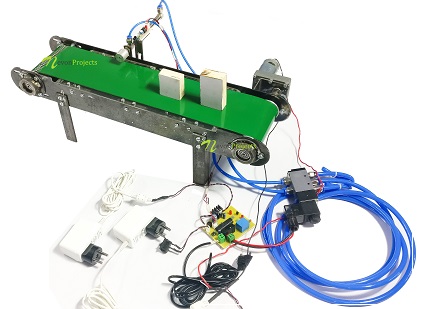

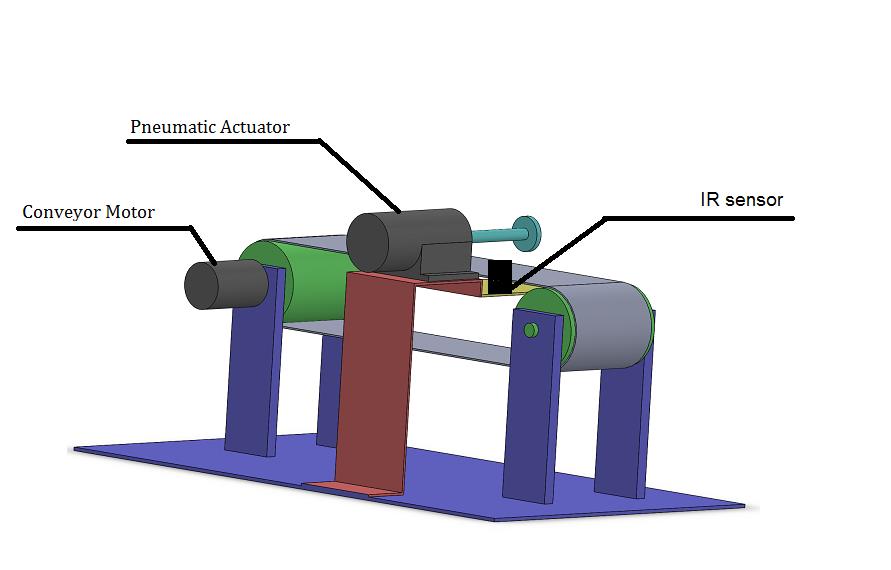

All product manufacturing units need to have a faulty product detection and separation system in order to maintain product quality and maintain a good reputation. So here we demonstrate such a system using a mini conveyer belt system. We propose to design and fabricate a faulty product detection and separation mechanism. Each product is different and thus has different mechanisms to detect faulty products. Here we detect faulty products based on product size. We use a sensor to detect each product height as products move over a conveyer belt. A defected product with height lower than minimum limit will be automatically detected as it moves on a conveyer belt and separated by a conveyer arm. Here we use rollers and rubber belt to develop a mini conveyer belt mechanism. This mechanism is operated by a motor. We use a proximity to detect product height and products with less than minimum height are detected as faulty products. The system uses a pneumatic cylinder mechanism using valves to separate the faulty product over the belt.

- Parts

- Pneumatic Actuator

- Pneumatic Pipes

- Valves

- Motor

- Shaft

- Rollers

- Supporting Frame

- Joints & Fixtures

- Screws & Bolts

- Advantages

- Automated Process

- Instant Separation

- Automated Quality Maintenance