Download Project Document/Synopsis

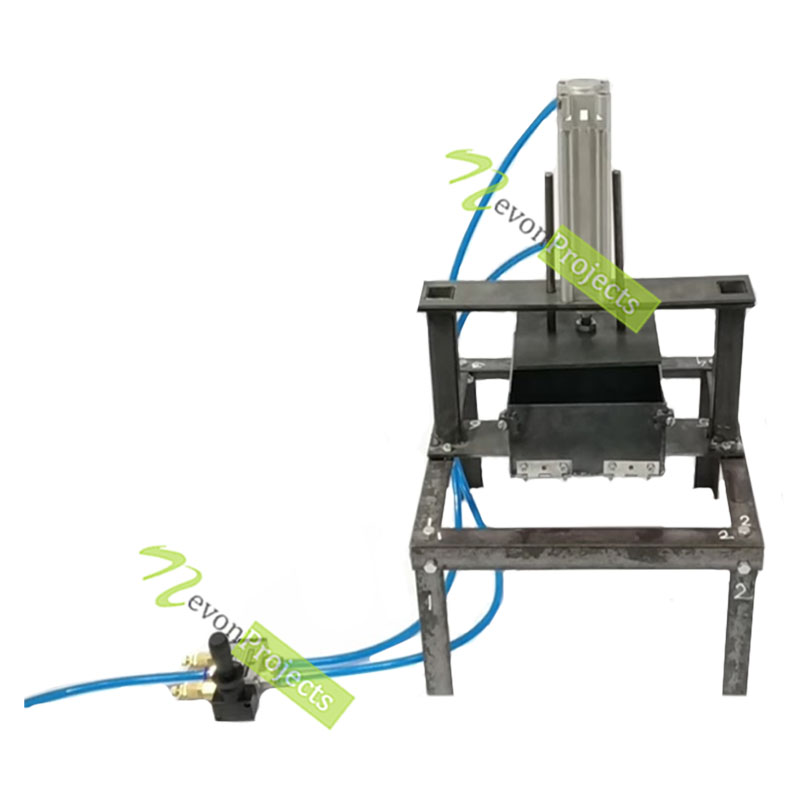

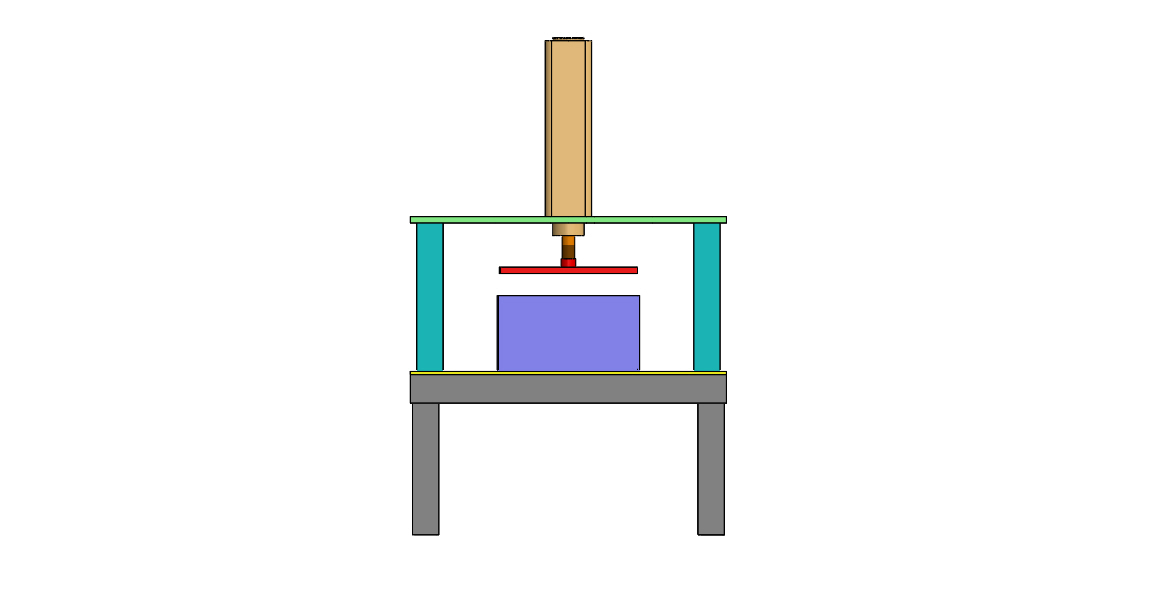

For vital metal forming, moulding is one of the important process in manufacturing components for wide applications in industries. The foundry environment and accuracy of cast part can be improved using automation in this field. Moulding process is affected by various factors like permeability, collapsibility, adhesiveness and much more, hence it is a much need to avoid defects in casting. Sand casting defects can cause tremendous problem in foundry. The packing of moulding sand will not be even throughout the moulding box even when human skilled labour is used. Hence design and fabrication of automatic pneumatic ramming machine for moulding the sand evenly throughout the box. The pneumatic rammer used for ramming the sand uniformly around the pattern has wide applications in small scale industries. To operate this rammer, an air compressor is required. For the operation of ramming a butt is attached to the bottom of the piston rod. In this project, the solenoid valve is used as a direction control valve. This solenoid valve management is led by the electronic control timing unit. The compressed air passes through the pneumatic double acting cylinder. The ram is fastened at one end of the pneumatic cylinder. The compressed air pushes the pneumatic cylinder in order that the piston moves downward by giving air supply in one direction of the pneumatic cylinder. The solenoid valve changes the airflow in the opposite way by the small-time delay. Due to the changing of the airflow direction, the pneumatic cylinder piston moves upward in this time. This airflow direction is controlled by the solenoid valve.

- Components

- Solenoid valve

- MS frame

- Pneumatic cylinder

- Ramming box

- MS Plate