Download Project Document/Synopsis

Bucket conveyors are used in industries for lifting materials at heighted containers or other conveyors. Bucket conveyors move items (regularly total or mass) vertically through responding buckets. The conveyor is made of an interconnected loop of box/buckets that stay level while moving from horizontal to vertical, keeping their items from pouring out. The conveyor is loaded with material at the front, or “boot”, and each bucket naturally deposits toward the finish of the run, otherwise called the discharge.

This interaction is a quick and programmed technique for vertical conveying, as similar buckets what get material are utilized to store it. The plan of these machines relies intensely upon the material being shipped as well as the desired height that it should travel, however they are solid and productive whenever made accurately. They perform best while moving dry, light, or powder material and are normally not used to move wet or slime like substances, as any buildup in the buckets will cause releasing issues.

Bucket conveyors are a famous decision for vertical conveying and track down many purposes in the biomass, concrete, glass, mining, power age, and paper businesses to give some examples. They keep item contained in discrete units, not at all like screw conveyors that homogenize the item and succeed in taking care of abrasive, free-streaming total.

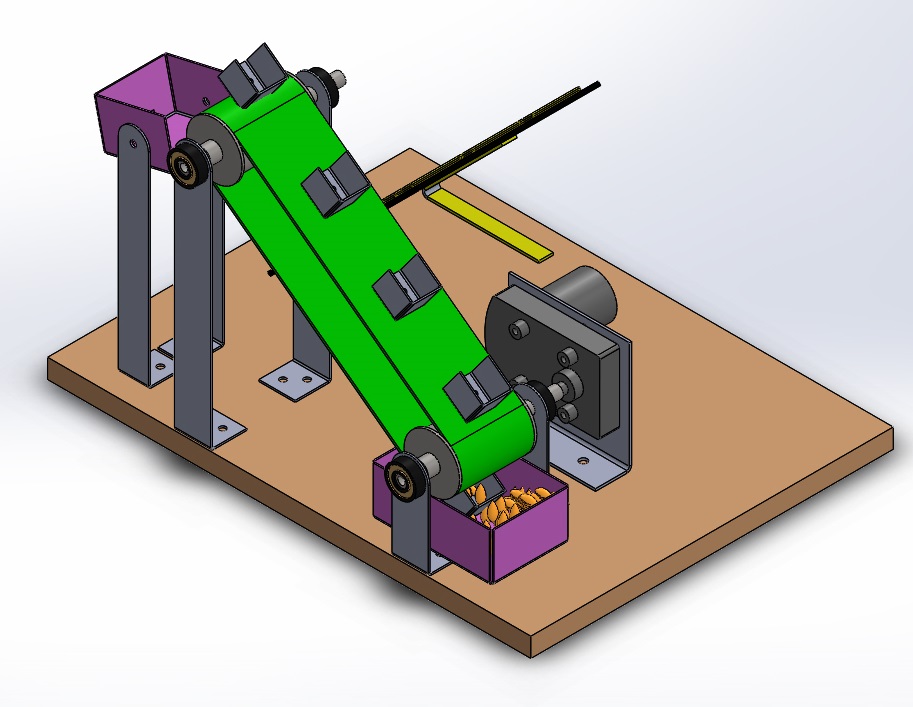

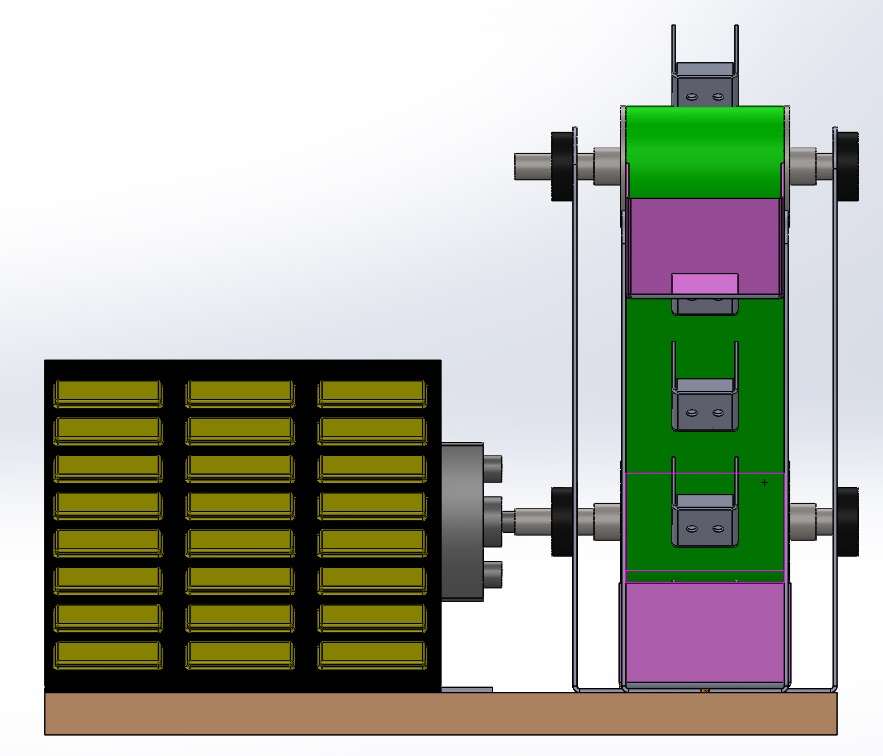

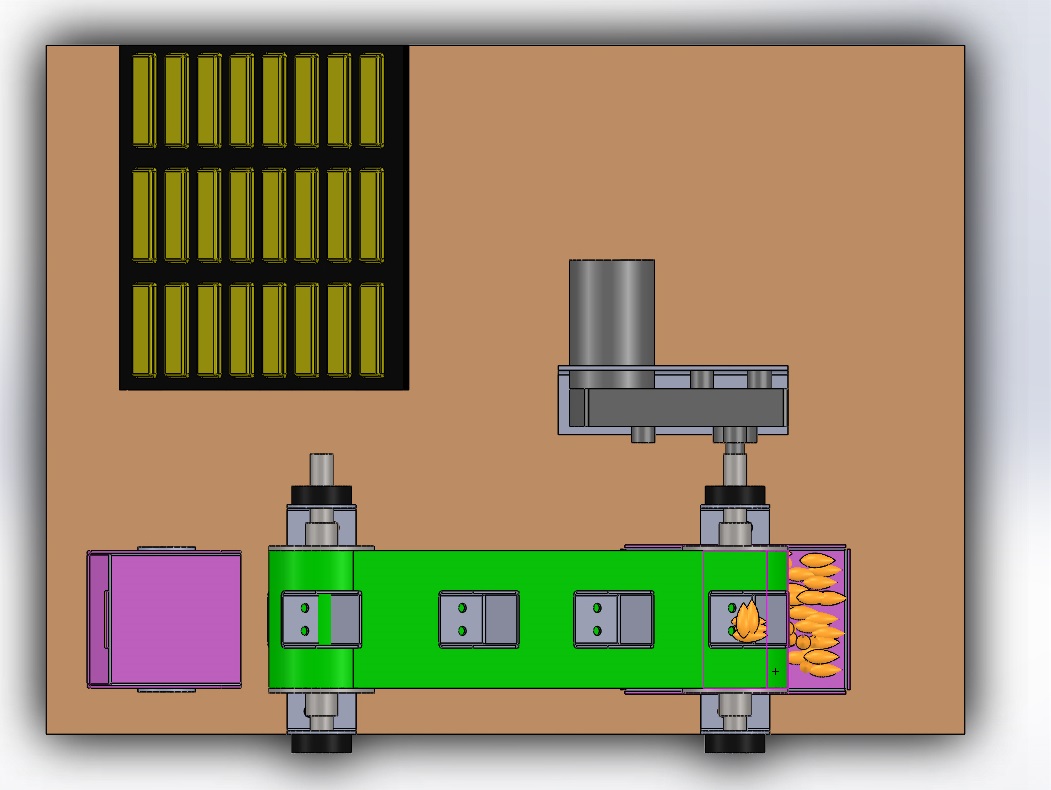

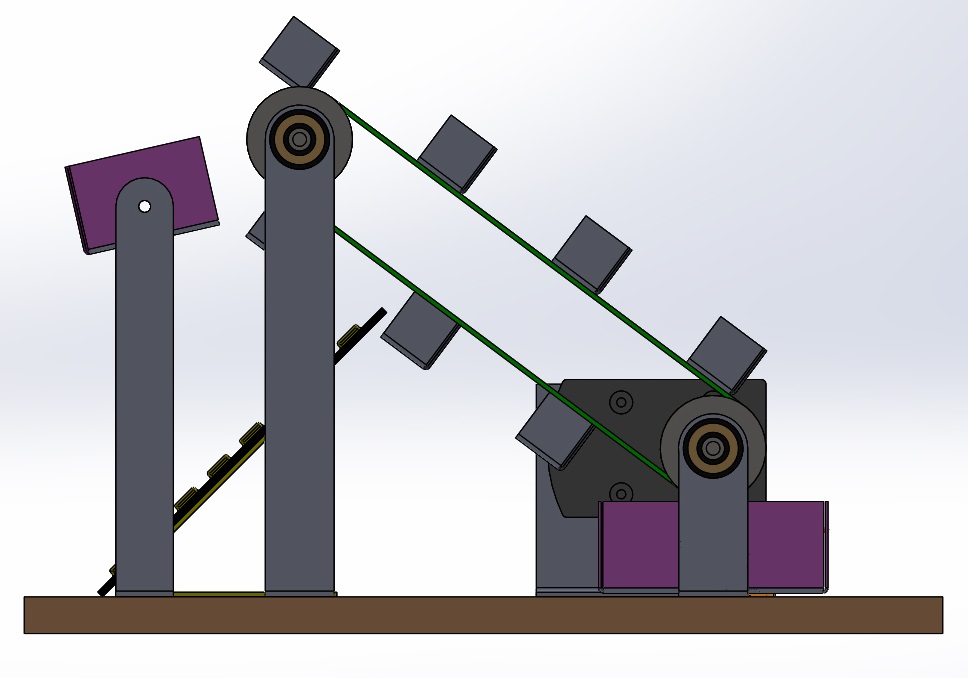

Well we hereby design a small working model of a bucket conveyor to study the design and fabrication process of a bucket conveyor system. We make use of a DC motor along with conveyor belt, buckets, discharge bin, rollers, bearings, shafts and supporting frame to develop the system.

When we power the DC motor, the system rotates the conveyor belt with buckets connected to it. The buckets can now carry proportionate loads of material vertically to be discharged. When a filled bucket reaches the discharge point. The motion along the top roller inverts the bucket onto the discharge container thus transferring the material.

- Components

- DC Geared Motors

- Shafts and Bearing

- Conveyor Belt

- Buckets

- Rollers

- Switches & Buttons

- Cables and Connectors

- Base Frame

- Supporting Frame