Download Project Document/Synopsis

Conveyors are a very critical part of manufacturing, packing and goods movement in industries. Most conveyors make use of belts powered by motors or rollers powered by chain drive or individual motors. These are the most used mechanisms for conveyors where goods are placed on the conveyors and move as per the motor speed, or using gravity conveyors that use bearing based rollers.

The problems with these conveyors are as follows:

- Goods movement is limited to speed of the conveyor motor.

- Motor speed cannot be more than a certain limit as it reduces torque.

- High cost of belts, motors and moving parts.

- Gravity conveyors require high cost of bearings and rollers.

- Moving parts require frequent maintenance and oiling.

- Wear and tear involved in these conveyors due to contact & friction involved.

Well here we take all these issues into account and develop a one of a kind futuristic conveyor concept that solves all these problems. From no wear and tear to low maintenance and higher goods speed this conveyor concept can revolutionize goods movement in industries.

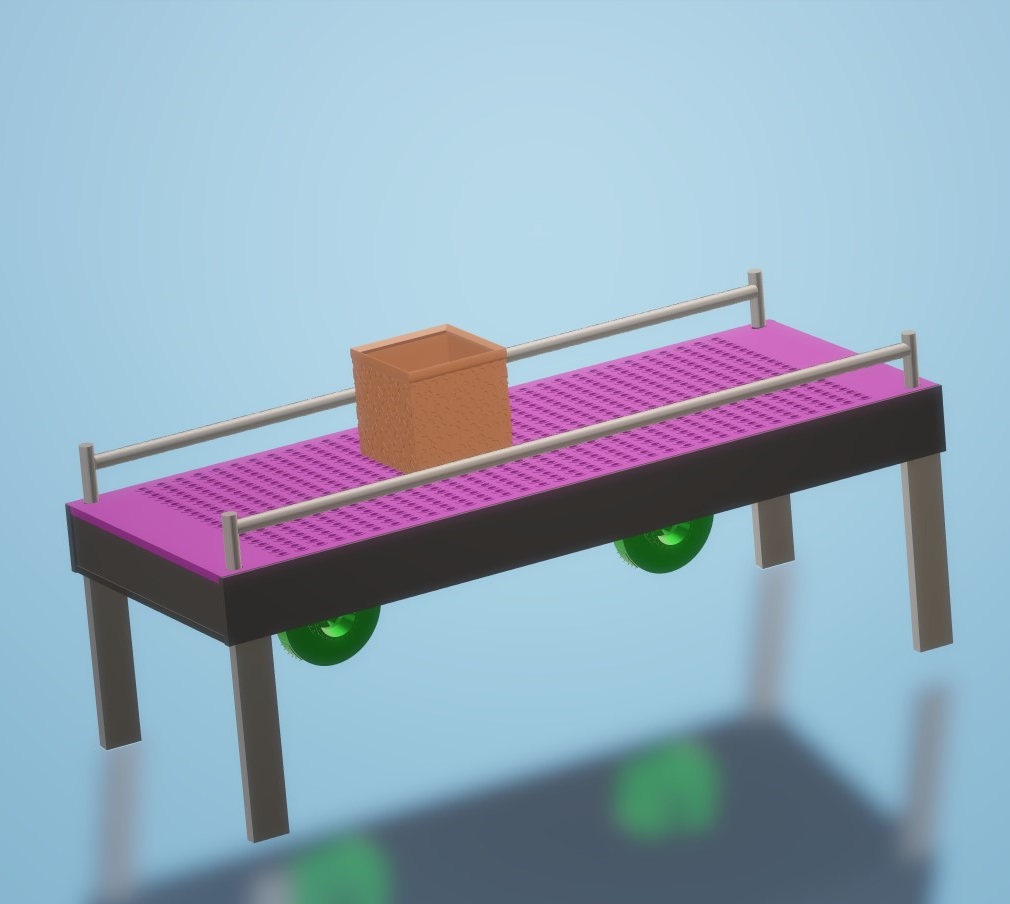

Here we develop a smart contactless conveyor where goods can move at very high speeds without ever coming in contact with the conveyor. This conveyor system makes use of air pressure to achieve this task. The upper layer of conveyor is made up of a glossy sheet that consists of drilled holes at accurate distance from one another. The lower section of the sheet is a hollow space that acts as a compressed air tank. The air pressure from the tank is gradually released through small holes drilled on the top conveyor surface.

The hole size and distance is calculated as per the size and weight of objects to be moved on the conveyor. The larger and heavier the object to be moved the larger the hole size and larger the distance between holes. Now as per the hole size and distancing, we hereby select appropriate air pumps to pump compressed air into the air tank. The more the hole size the powerful the pump must be as per calculations. Well we here use a hole size and appropriate pump to move small goods/product boxes.

The conveyor has 4 legs attached to it that are mounted in a way to provide a slope for gravity based movement. In case slope cannot be provided, separate air pressure/pneumatic piston can also be used to set the goods in motion. The conveyor has 2 side rails to prevent goods from falling from the conveyor. Once the object is set in motion it hovers over the conveyor in travels seamlessly in pushed direction without friction. Thus this system provides a modern contactless goods transport system that has no contact, lower maintenance and very less moving parts for easy goods movement.

- Compenents

- Air Pumps

- Holed Sheet

- Side Support Rods/Rails

- Conveyor Legs

- Pipes and Joints

- Base Frame

- Supporting Frame

- Mounts and Joints

- Nuts and Bolts

- Screws and Joints

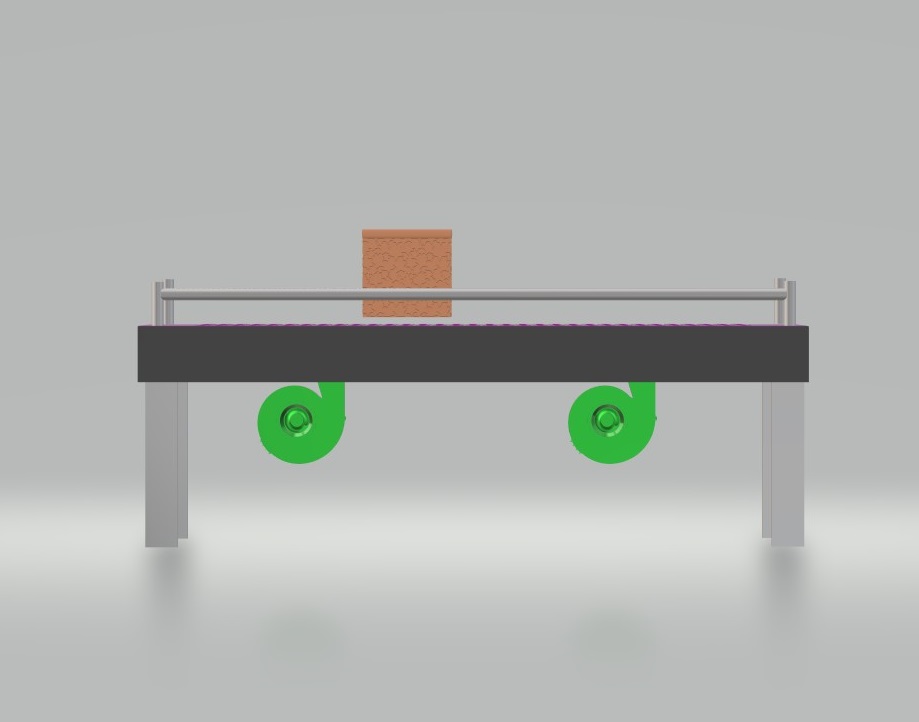

Front View

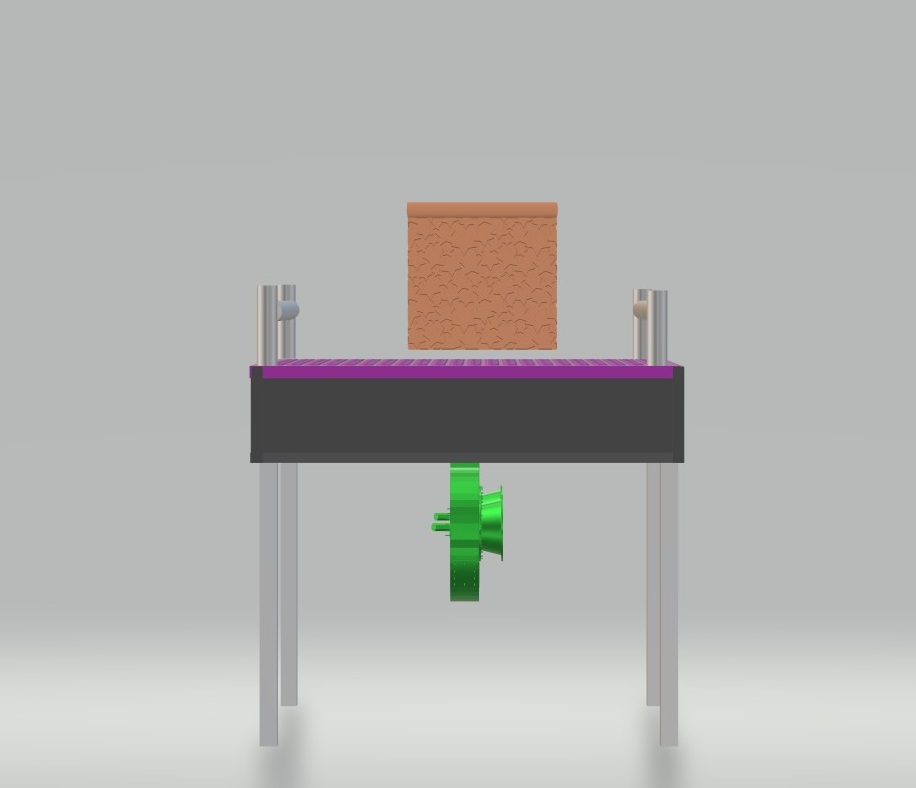

Side Views